How to Build a Stacking Rings Set: Choosing the Perfect Wedding Band June 12 2016 1 Comment

One of the most common issues my buyers encounter is difficulty in building a set of rings that "look right" together. The most meaningful set of stacking rings most of us will ever wear is our wedding set, and many brides have a hard time figuring out how to match wedding bands to their engagement rings.

Most jewelry wearers assume that if you match the color and style of the engagement ring, it's all good, right? An advanced wearer might even consider matching the band's width (the measurement of the visible portion of the ring when worn, or the top). However, the most important and commonly overlooked factor is the band's height, which is the measurement of the profile of the band (visible when viewed from the side). This dimension may also be referred to as the band's thickness.

When reading a description from an online listing, a band's measurements will usually be written in the width x height format. For example, a ring that's "2mm x 1mm" is 2mm wide and 1mm high. A band that's designated as "full round" will only have one dimension listed, because it measures the same from any angle. While most people never consider a ring's height, I'll explain here why it's crucial to pay attention to all dimensions.

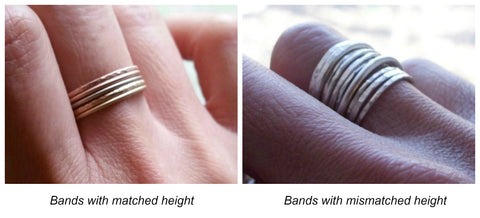

The bands below are of matching width but different heights.

With regular stacking rings sets, fashionistas can achieve an artier effect by intentionally mismatching band heights:

But apply this principle to a wedding set and things start to look really wonky! Disclaimer: I'm sorry I don't have prettier rings to show here, but since I don't carry pre-made stock, most of the rings pictured in these demonstrations are from my errata and scrap pile!

As you can see, though most of the "important" factors are matched - white color and 2mm width - the mismatched height of the bands throws things off balance. As the height gets closer to matching (right) the set looks a bit more balanced, but even a tiny difference of half a millimeter makes a visual impact.

Here's How It's Done

Even though the "important" factors - color and width - are totally mismatched here, the set still looks relatively balanced because the height of the bands match. Yay!

To drive the point home, below are some plain bands to look at without the giant stone to distract you.

Bands with Mismatched Height and Width

Left: 1mm full-round hammered matte rose gold band with 1.6mm full-round hammered matte yellow gold band.

Right: 2mm x 1.5mm diamond platinum band with 1mm x 1mm palladium white gold band.

Bands with the Same Width, but Mismatched Height

Left: 1.5mm x .75 half-round rose gold band with 1.6mm full-round rose gold band

Center: 2mm x 1mm hammered white gold band with 2mm full-round white gold band

Right: 2mm x 1.5mm diamond platinum band with 2mm full-round white gold band

Bands with Matching Height

Left: 5mm x 1.5mm hammered matte gold band with 1.6mm full-round hammered matte gold band

Center: 2mm x 1.5 half-round white gold band with 1.6mm full-round rose gold band

Right: 1mm x 1mm palladium white gold band with 1.2mm x .8mm half-round rose gold band

I hope you've found this helpful! Feel free to email me if you need additional assistance. I'm always happy to answer questions!

Comments

Shari D. on April 14 2020 at 12:21AM

Oh, thank you – THANK you!! Finally! 🙆🏼♀️Someone who not only truly understands, but brings out in a specific post, the importance of understanding the concept, and the process of determining the thickness (as well as the width) and matching the thickness of the shanks of rings💍to be worn together on the same finger, especially a wedding set, and why it is visually important.

This was not nearly as much of a problem 40 or 50 years ago (or more) when wedding and engagement rings💍were (more often than not) sold in pre-matched sets, which became especially popular during and after WWII; and wedding bands came in a few measured shank dimensions and sizes, generally the traditional “D” shaped style, flat on the inside against the finger, and domed to a certain degree on the outside, from practically flat to highly arched.

Comfort fit styles (based on the English “court style” which had been around for many years prior) did not become patented by Benchmark and available to U.S. markets until 1975 (when my husband and I became engaged, and I became very busy shopping for wedding bands!) We got a set of plain, 14kt white gold “Comfort Fit” bands, mostly to go with my simple solitaire. Most of our friends had not even heard of them yet, and the few who had, either didn’t want to pay the extra price, based on their extra gold weight needed to accommodate the design, and its newly patented status, or were already married and had their rings. We got lucky in that even though we had a limited budget to pay for our wedding, I believed in certain things, such as wedding rings to be worn for a lifetime, you invest in the best quality you can possibly afford, even to the detriment of less important, and less durable items. And we did so. Still have them after 43 years!

Engagement ring shanks were also much more standardized, and easier to match up, even with bands made by different producers and sold by different vendors.

I’ve always been much more traditionally-minded when it comes to this concept, having grown up in the 1960’s to mid 70’s, with a bench jeweler for a grandfather. I saw many sets of different vintages when I was growing up, as he did a great deal of resizing, repair work such as retipping, and remounting of the more important sized vintage diamonds for newer owners, usually in the same family. I learned a great deal from watching him work.

I can’t TELL you how many times, especially over the years that rings have been marketed on the internet, that I have tried desperately to explain, define, and/or demonstrate the concept of shank or band thickness vs width, not only to vendors who don’t produce their own merchandise, but to some who do! (Or at least claim to!) The confusion between the two measurements runs wild and rampant between them, and can be beyond frustrating, bordering on infuriating!🤦🏼♀️

Even when the opportunity exists to provide photos and clearly labeled diagrams, there is still plenty of confusion to be found on their part.

One time in particular, I had to finally break down the concept🔎of thickness vs width by comparing the dimensions of an 8X11" single piece of paper📄vs an 8X11" piece of plywood! The only dimensional difference WAS the thickness, and it finally made the lightbulb💡"flicker on" for the person to whom I was talking. Prior to that moment, the individual absolutely insisted that the thickness of a particular ring was 4.5mm! Try as I might, I couldn’t seem to get through to him that it would be practically impossible to comfortably wear a ring shank of such dimensions! And then, the “paper vs plywood” comparison dawned on me, and the problem was solved!

Honestly, the thickest bands I have ever seen were 3mm at the thickest point, and I’m not too sure they sold very many of them! Besides the expense, the comfort factor seemed somewhat dubious.

ANYWAY, thanks again for your post, and the consideration of its importance! I was beginning to wonder if I was the ONLY person who really cared! (If this is too long, seems to wander off topic, or just isn’t interesting from a historical standpoint, please feel free to edit it down for size.) I shall continue reading through your posts, and I’m sure that I will find others of continuing interest!